How can we help you today?

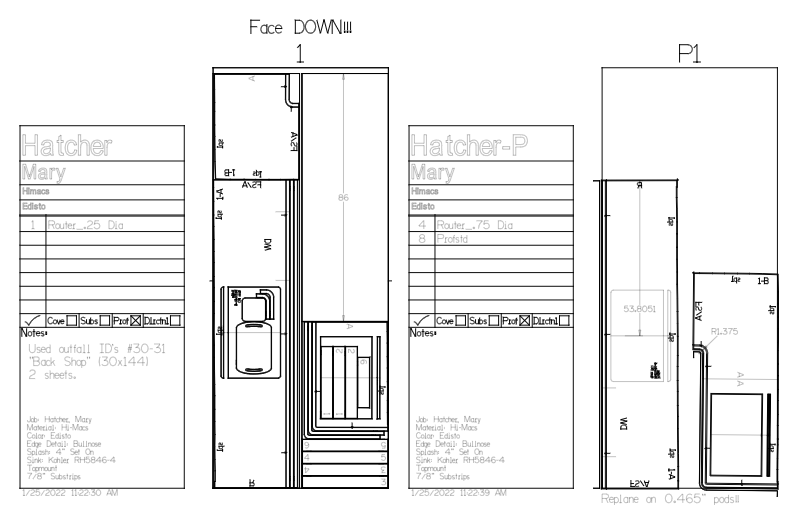

Residential Solid Surface

Our programming approach fully integrates your CNC into the fabrication process. From your templated drawings, we provide programs to cut every piece and reintroduce each countertop for finish machining to exact size.

Benefits:

- All parts Ready To Assemble

- Maximize material use through nesting optimization

- Track and utilize material outfall

- Apply large profiles at the CNC during finish machining

- Fabricate cove on the CNC including inside cove corners

- Optionally provide custom machined substrates to speed fabrication and installation

Commercial Solid Surface

We are happy to share our extensive experience with both large scale and highly complex commercial solid surface projects.

Experience:

- Wall cladding / Column wraps / Spiral stairs

- Custom Reception Desks / Nurse Stations

- Illumination with transluscent materials

- Cove to No Drip transitions

- Waterfall end details

- Job batching / sequencing for maximum throughput

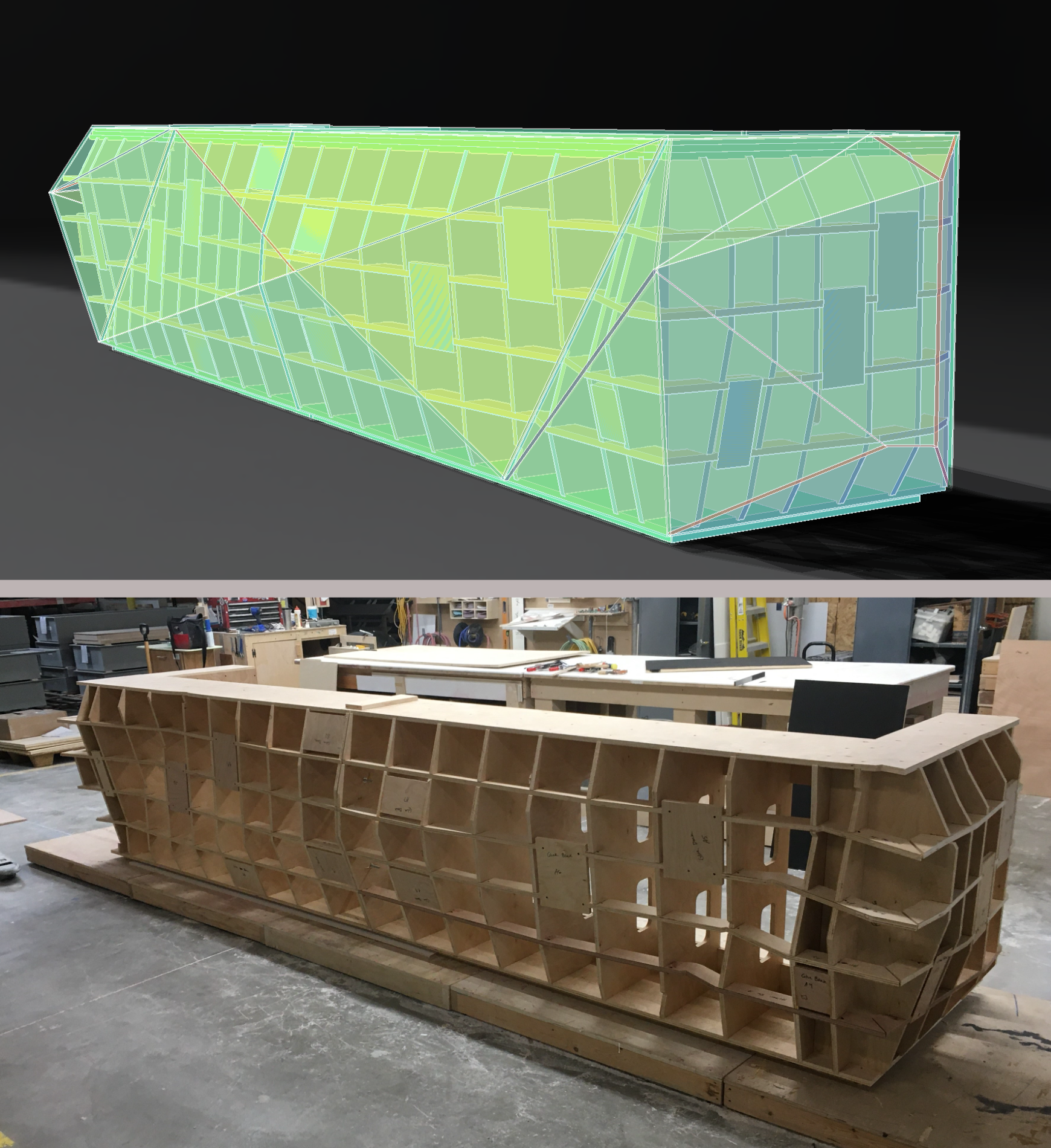

Custom Thermoforming

Explore the unending possibilities for complex curved shapes with thermoforming. Never tell the architect no again!

Capabilities:

- Complex solid modeling and rendering

- Solid carved mold programming for 3 and 5 Axis CNCs

- Design of ribbed forms for unidirectional bends

- Create trim and assembly jigs for shop fabrication

- 5 axis programming for final part trimming of complex shapes

Die Wall Fabrication

We believe die walls should assemble like a model... just in full scale!

Approach:

- All parts key together for superior strength

- CNC machined pieces ensure accuracy throughout all fabrication steps

- Reduced labor skill required for fabrication

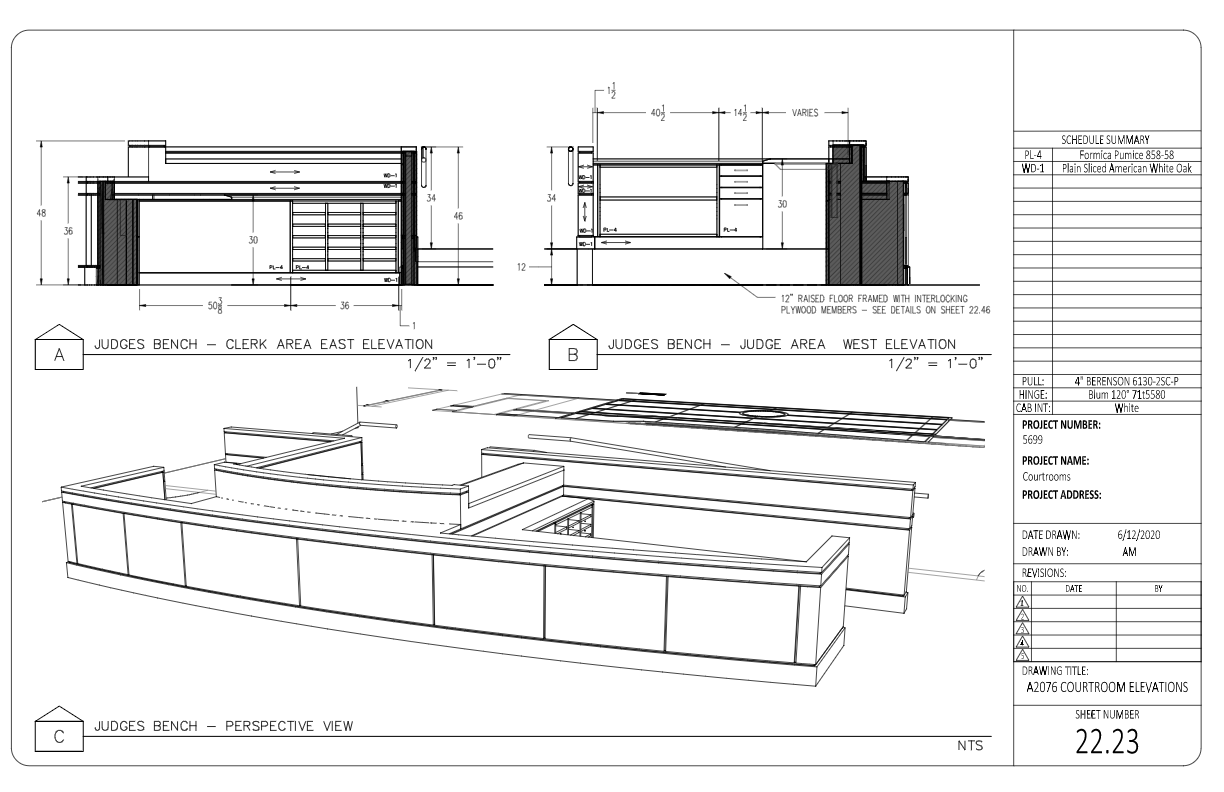

Millwork Submittals

Nearly two decades of experience with Microvellum, a leading software package for the millwork industry.

Services:

- Professional quality submittal packages

- Experience with Microvellum library development and custom product creation

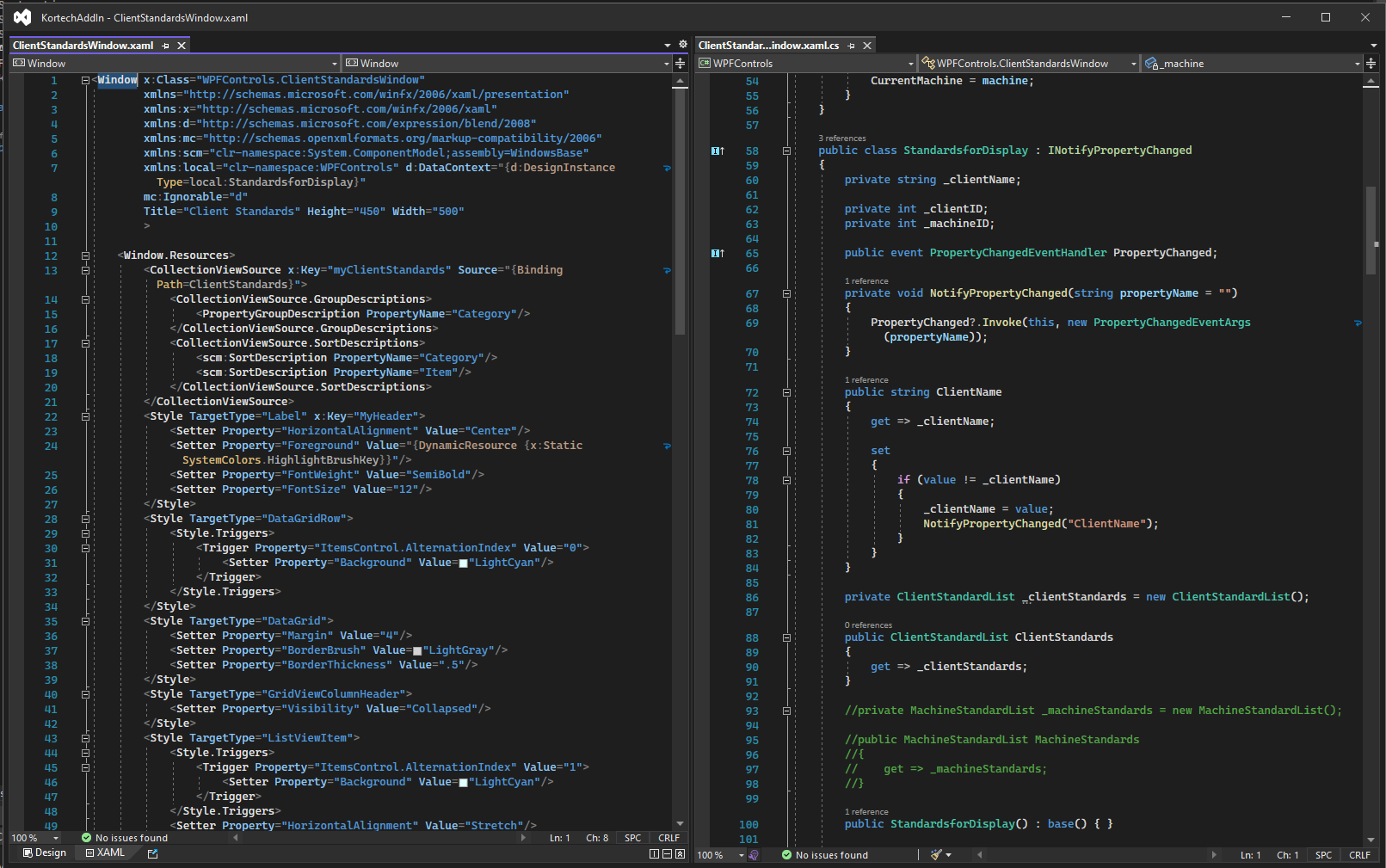

AlphaCAM Post Processor Creation and Custom Software Development

Post Processors:

- Post Processors for FANUC controlled 3, 4, and 5 axis machines.

- Now also supporting B&R, Delta, and WinCNC controllers.

- Written in modern .NET language for enhanced speed and enlarged feature set

- Support for aggregates, multidrill integration, saw heads, etc.

- Utilize Fanuc canned cycles to enable additional options in drilling, pecking and boring operations

- Additional options:

- Masked tool changes

- Automatic vacuum zone control (dependant on machine capability)

- Custom user interface based on client requirements

- Twin table support including pendulum operation

- Slave programming of multi-head machines

- Five Axis specific features:

- Automatic prewind to utilize all available C axis rotation stroke

- Calculates best axis rotation combination to minimize movement between cuts

- Use tilted work planes to allow for tool cutter compensation on 3+2 machining

- Set R value for AI Contour control per AlphaCAM operation

- Use of tool center point control for safe transitions between cutting moves and during prewind

Custom Software Development:

- Integrate additional aspects of your business processes to allow for streamlined porting of information between divisions

- Experience with Azure cloud services to minimize on-site infrastucture costs and create additional options for remote work